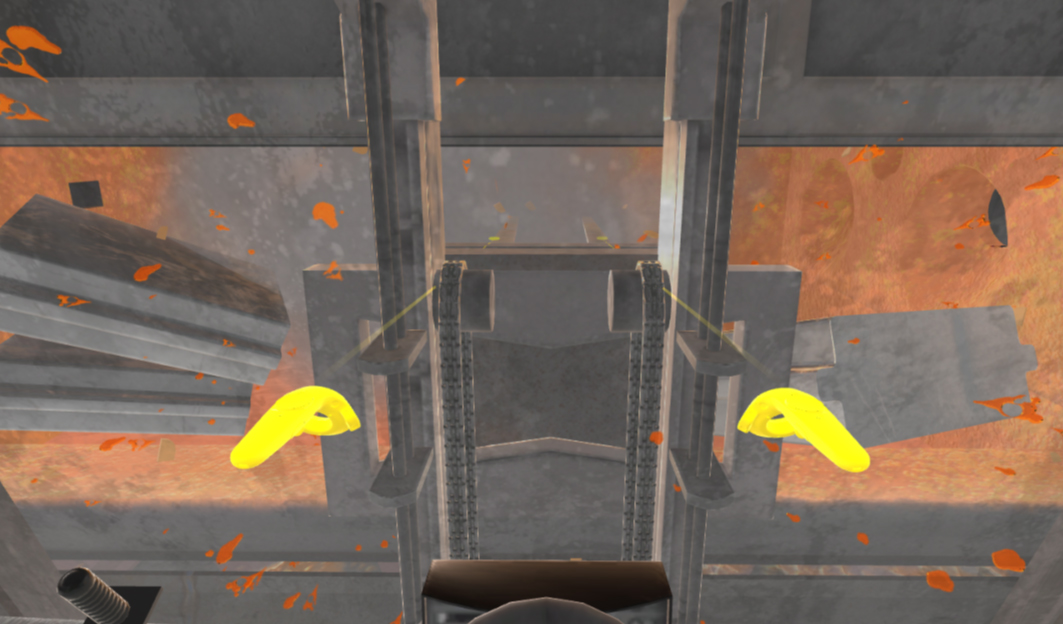

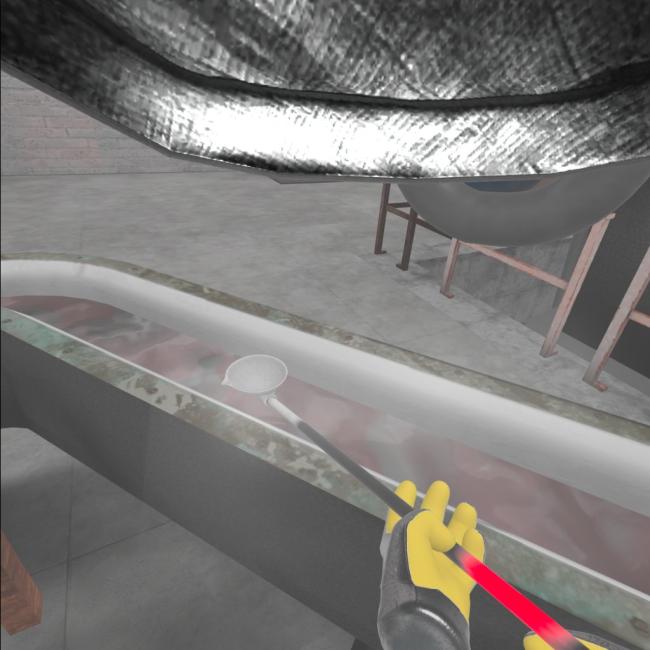

MOLTEN METAL VR is an immersive simulator for training in procedures related to liquid metal in an aluminum foundry.

Our missions are manifold and cover the 3 phases of aluminum recycling from start to finish:

- Inspection and placing of aluminum scrap in the furnace

- Chemical correction of the furnace with addition of metals (copper, magnesium, manganese, etc.)

- Equipment, handling and sampling of a metal pawn at the furnace outlet

71

11

4

Equipment deployed

54 Meta Quest 2 headsets + 17 Android tablets

Equipped sites

France, Switzerland, Germany,

United States and Czech Republic

Different languages

French, English, German, Czech

The simulator is highly realistic, representing the complexity of real-life work situations thanks to extensive parameter customization (furnace temperature and condition, weather conditions, potential equipment faults, etc.).

Each parameter will influence the scenario conditions and have different consequences depending on the apprentice's actions.

The simulation is monitored by an experienced trainer who can see the user 's actions and choices in real time, providing immediate feedback on what has been learned and what reflexes are required in real-life conditions.

Learn

professional techniques in a realistic environment

- Creation of a complete industrial environment with a furnace and detailed installations.

- Designed for stand-alone VR helmets (Oculus Quest)

- Multiplayer / cooperative mode

- Complete simulation of a complex procedure

Pedagogical tool at the service

of the trainer

- Multiple scenario support

- Pedagogical report with precise behavioral follow-up

- Train many people at the same time and collaborate without the extra travel costs and more.

Learning by doing,

enhanced memorization

- Train as you would in real life, thanks to a high-fidelity simulation of a complex procedure

- Progress through the process step by step with your peers and improve your knowledge by doing.

- Train as many times as you need with unlimited scenario possibilities